Your cart is currently empty!

How Students Solved Their Own Problem: The Air Hockey Puck Project

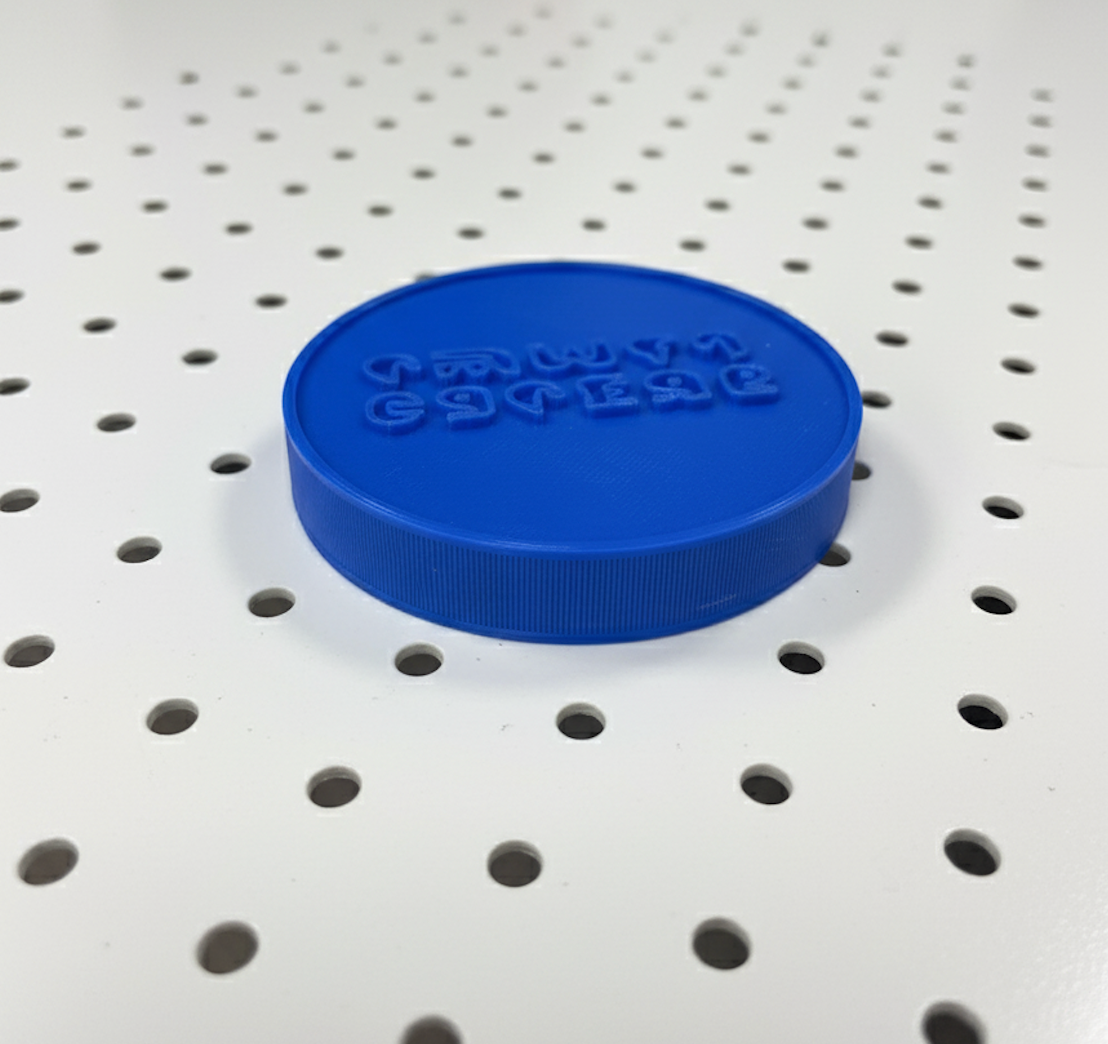

“Can we print a puck on the 3D printer?”

The question came from sixth graders who were tired of their table air hockey game sitting unused. Every campus had these tables – popular gathering spots during breaks. But the pucks broke easily, and without spares, the games couldn’t continue.

This wasn’t a teacher asking for a classroom resource. This wasn’t an assignment. This was students identifying a real problem in their daily lives and asking if they could fix it themselves.

The answer, of course, was yes.

Assembling the Problem-Solvers

We gathered five to six students who were genuinely interested in solving this problem. Not the whole class – just the ones who cared enough to invest time in the design process.

Together with their computer science teacher, I facilitated a brainstorming session. But the questions came from the students:

How could we make the puck more durable than the original? What measurements would we need? How could we make it clear this was custom-made, not just a replacement?

These weren’t hypothetical design challenges. These were real constraints for a real object they actually needed.

From Broken Puck to Design

The students started with what they had: a broken puck. They measured it carefully, recording every dimension. They had to get this right – too big or too small and it wouldn’t work on the table.

Then came the innovation thinking. What could they change to make it better?

Someone suggested increasing the infill – the internal structure of the print. Higher infill meant more material, more density, more durability. It would take longer to print and use more filament, but if it lasted longer, it was worth it.

Another student proposed adding the Green School logo. This would be their puck, not just a generic replacement.

They finalized the design and hit print.

The First Test

When the first puck came off the printer, the excitement was palpable. They had designed this. They had problem-solved together. Now came the real test: would it actually work?

They took it to the air hockey table and started playing.

But this wasn’t just casual gaming anymore. They were observing. How did the puck move compared to the original? Did the increased infill affect the glide? How was it holding up?

The students were so invested in their solution working that they asked other students to be careful with it, to treat it gently. They became protective of something they’d created.

We agreed to reconvene after a week of real-world testing to evaluate and discuss what needed to change.

When It Broke (But Taught Them More)

A week later, we gathered again. The puck had broken – but not completely. The borders were damaged while the center held strong.

In a traditional classroom, this might have felt like failure. But these students saw it differently. They had data now. They understood exactly what needed to improve.

The problem wasn’t the overall design or the infill density. It was the borders – the edges that took the most impact during play.

Back to Tinkercad. They redesigned the border structure, reinforcing the edges, rethinking how those vulnerable points were constructed.

They printed version two.

The Solution That Worked

This time, it held.

The redesigned puck withstood the gameplay. It glided properly. It was durable where it needed to be. The problem was genuinely solved.

That puck is still in use.

But more important than the puck itself was what the students experienced: the complete cycle of design thinking in action.

What Made This Different

I’ve implemented many 3D printing projects in schools. I’ve seen students create impressive designs, beautiful objects, complex models. But this project had something many others didn’t: authentic ownership.

The students didn’t design this puck because a teacher assigned it. They designed it because they wanted to play air hockey and couldn’t. The problem was real. The stakes were real. The testing was real.

When the first version broke, they weren’t discouraged – they were motivated to iterate. When the second version worked, the pride wasn’t about getting a good grade. It was about solving something that mattered to them.

The Skills They Didn’t Know They Were Learning

Ask those sixth graders what they learned, and they might say “how to design a puck.”

But watch what actually happened, and you see:

Problem identification – Recognizing a solvable problem in their environment

Measurement and precision – Understanding that dimensions matter

Material science basics – Learning how infill affects strength and performance

Iterative design – Accepting that first versions often need improvement

Data collection – Observing and documenting real-world performance

Collaborative problem-solving – Working together through multiple design phases

Resilience – Viewing “failure” as information, not defeat

All of this emerged organically because they were solving a problem they actually cared about.

Why This Matters

3D printing in education isn’t ultimately about the technology. It’s about giving students tools to solve real problems in their world.

When we limit 3D printing to teacher-designed projects and curriculum-mandated lessons, we miss the most powerful application: empowering students to identify problems and create solutions themselves.

The air hockey puck wasn’t in any curriculum. No standards document required it. But those sixth graders learned more about design, engineering, and problem-solving than many formal lessons could teach – because it mattered to them.

That’s when 3D printing becomes transformative: when students stop being recipients of educational content and become creators of solutions.

One response to “How Students Solved Their Own Problem: The Air Hockey Puck Project”

-

restored my hopes for gen alpha

Leave a Reply