If you’ve ventured into the world of 3D printing, chances are you’ve already encountered PLA (Polylactic Acid) filament. It’s often the first material recommended for beginners, and for good reason! But what exactly is this ubiquitous plastic, and why has it become such a staple in the additive manufacturing community? Let’s take a closer look.

What is PLA Made Of?

Unlike many other plastics derived from petroleum, PLA boasts a more sustainable origin. It’s a bioplastic, meaning it’s made from renewable resources. The primary ingredients are starches extracted from plants like corn, sugarcane, or tapioca. Through a process of fermentation and polymerization, these plant sugars are transformed into lactic acid, which is then converted into polylactic acid – the polymer that forms our beloved PLA filament. This makes PLA a much more environmentally friendly option compared to its synthetic counterparts, as it’s both biodegradable and compostable under the right industrial conditions.

The Pluses of Printing with PLA

PLA has earned its popularity through a host of advantages:

- Ease of Use: This is perhaps its biggest selling point. PLA prints at relatively low temperatures (typically 190-220°C for the hot end and 0-60°C for the print bed, though a heated bed isn’t strictly necessary). It also has minimal warping, making it forgiving for beginners and reliable for larger prints. You’ll rarely hear complaints about adhesion issues with PLA.

- Low Odor: Unlike ABS, which can emit strong, sometimes unpleasant fumes during printing, PLA has a very mild, often slightly sweet odor. This makes it more suitable for use in homes or office environments without special ventilation.

- Good Detail and Finish: PLA typically produces prints with a smooth, glossy finish and excellent detail resolution. This makes it ideal for aesthetic models, figurines, and prototypes where visual quality is paramount.

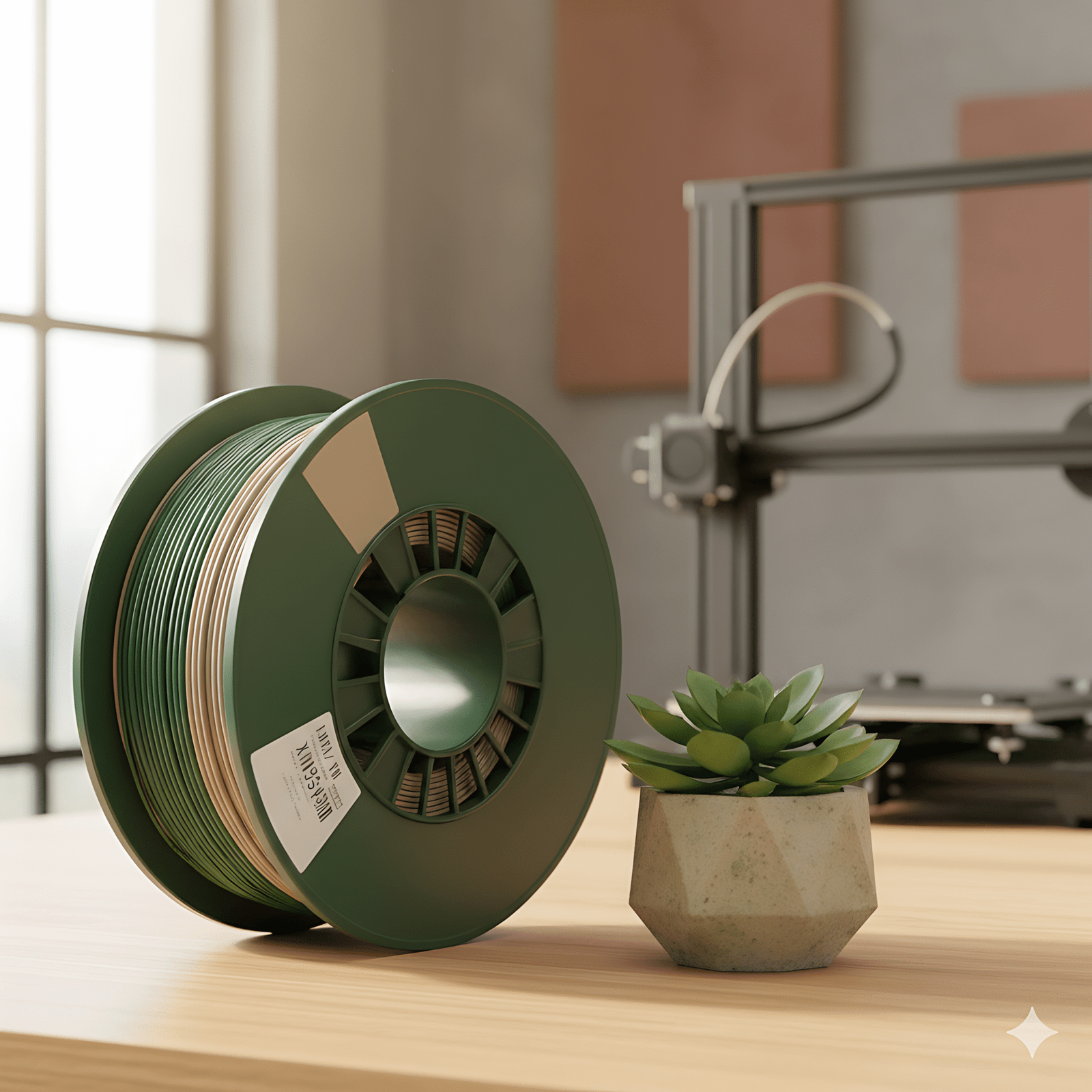

- Wide Range of Colors and Specialty Filaments: The market is flooded with PLA in almost every color imaginable. Beyond standard hues, you can find specialty PLAs infused with glitter, wood particles, metallic flecks, glow-in-the-dark pigments, and even silk-like finishes, offering incredible versatility for creative projects.

- Biodegradability: As mentioned, its plant-based origin means PLA can break down into natural compounds under specific composting conditions, reducing its environmental impact compared to traditional plastics.

The Minuses of Printing with PLA

While PLA is fantastic, it’s not without its limitations:

- Lower Temperature Resistance: This is its most significant drawback. PLA begins to soften and deform at relatively low temperatures (around 60°C). This makes it unsuitable for parts that will be exposed to heat, such as components in direct sunlight, automotive parts, or functional parts used in warm environments.

- Brittleness: Compared to materials like ABS or PETG, PLA can be more brittle. Thin walls or intricate features might be prone to breaking under stress, especially if dropped.

- UV Degradation: Prolonged exposure to UV light (like sunlight) can cause PLA to become brittle and discolored over time. This further limits its suitability for outdoor applications.

- Limited Chemical Resistance: PLA doesn’t hold up well against many solvents, which can be a disadvantage for certain post-processing techniques or specific functional applications.

In Conclusion

PLA remains an undisputed champion in the 3D printing world, especially for hobbyists, educators, and those creating decorative or prototyping prints. Its ease of use, aesthetic appeal, and eco-friendly credentials make it an excellent starting point and a reliable material for countless projects. Just remember its temperature limitations, and you’ll find PLA to be an incredibly versatile and rewarding filament to work with.

Here’s an example of a 3D print made with PLA filament:

Leave a Reply