Your cart is currently empty!

Scaling Up and the Humidity Problem: Troubleshooting the Anycubic Kobra S1

After a few months of success with the FlashForge, we made a significant decision: we purchased ten Anycubic Kobra S1 printers—one for our use, and nine to sell on our upcoming website, 3DVinci. Along with the printers came a massive 120 kg of Anycubic filament in multiple colors. It gave us a lot of opportunity for learning.

Why the Anycubic Kobra S1?

The Kobra S1 offered several compelling upgrades. It could print with four colors, delivered higher quality prints, and came with the ACE Pro system—which included a built-in filament dryer. At the time, the dryer seemed like a convenient extra feature. We didn’t yet understand how critical it would become.

We also invested heavily in filament: 10 kg each of blue, grey, yellow, black, white, and red. It was a major step up from our single-printer operation.

The Impressive Start

After assembly, which was straightforward but required attention to detail, the Kobra impressed us immediately. Our first test print was a multi-color Night Fury keychain with yellow eyes, and the quality was noticeably better than what we’d been getting from the FlashForge. The machine looked sleek, printed beautifully, and everything seemed promising.

For the first month or two, the Anycubic performed flawlessly.

When Things Went Wrong

Then the problems started. The printer began experiencing recurring extruder clogs and failed prints. Layers wouldn’t adhere properly. Stringing became a constant issue. Prints that should have worked perfectly were failing halfway through.

Here’s what I learned: the real test of a 3D printer owner isn’t printing—it’s troubleshooting.

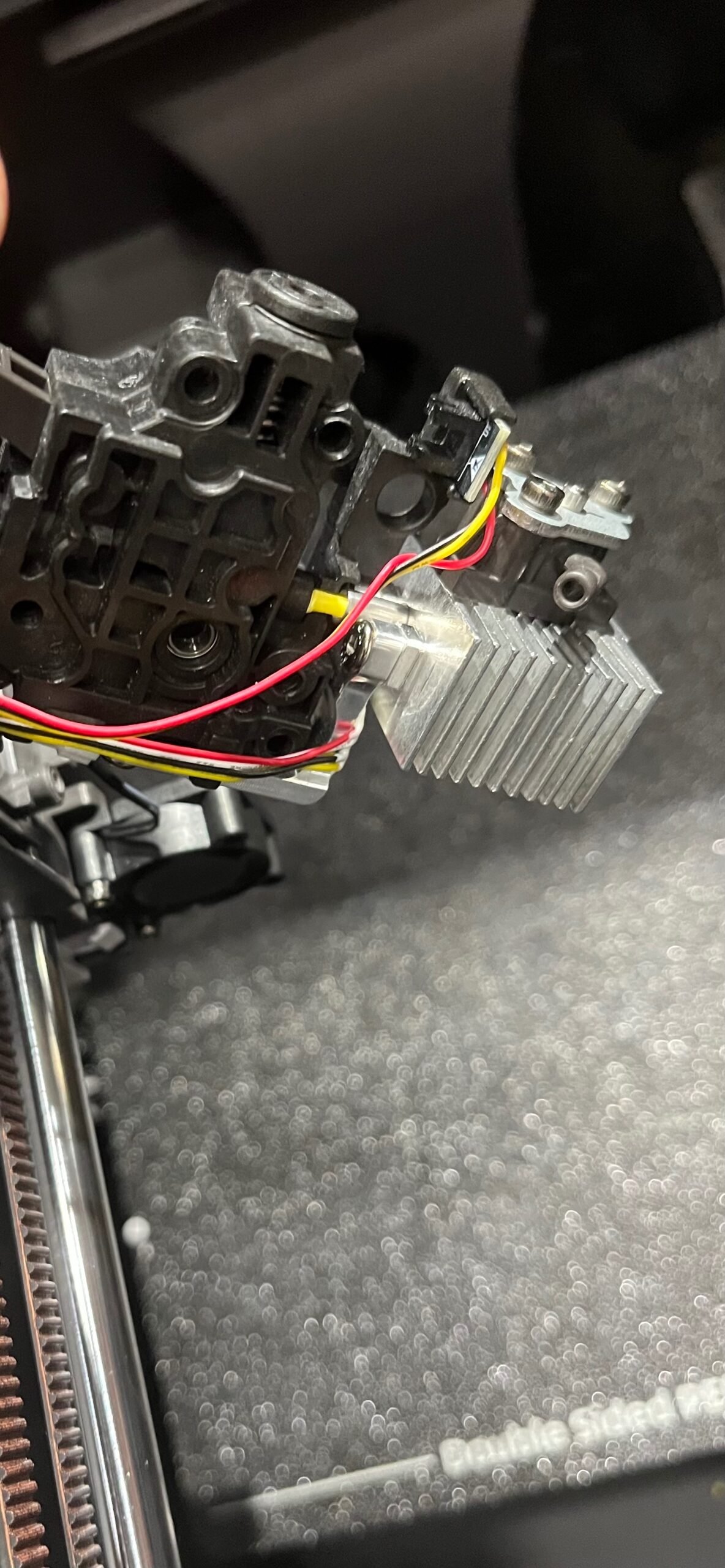

I took the extruder apart multiple times. I verified the filament could reach the extruder. I cleaned the nozzle thoroughly, checking for any blockages. Everything looked fine mechanically, but the printer still couldn’t extrude filament properly. There were clicking sounds coming from the extruder and occasional popping noises during printing. Sometimes there was even a faint burning smell.

We tried everything we could think of. Eventually, we even had to replace the extruder entirely, unboxing one of the printers we’d planned to sell just to get a replacement part.

But the problems persisted.

The Discovery: Humidity

The breakthrough came when we finally connected the dots. The ACE Pro system had a built-in dryer. The filament labels mentioned drying before use. We’d seen these things but hadn’t understood their importance.

The issue was moisture absorption. PLA filament, especially in our climate, was absorbing humidity from the air. That moisture was turning to steam inside the hot end, causing the popping sounds, the poor extrusion, the layer adhesion problems, and the burning smell. The “clogs” weren’t physical blockages—they were the result of trying to print with wet filament.

The Solution and What We Learned

Once we started properly drying our filament before each use, the problems significantly improved. We typically run the dryer for 4 hours, which is the basic preset on the ACE Pro system.

If you’re experiencing similar issues, here’s what to watch for:

- Clicking or popping sounds during printing—this is moisture turning to steam

- Poor layer adhesion where layers don’t bond properly

- Excessive stringing between parts of the print

- A faint burning smell during printing

- Inconsistent extrusion even when the nozzle appears clean

- The error massage about filament clogging

The lesson: Read the filament specifications carefully. If it says to dry before use, that’s not optional—it’s critical. The built-in dryer wasn’t just a convenience feature; it was an essential part of the printing process.

Moving Forward

This experience taught me that 3D printing isn’t just about getting the settings right—it’s about understanding the materials you’re working with. Filament isn’t just plastic; it’s a material that interacts with its environment. Temperature, humidity, and storage conditions all matter.

Troubleshooting those clogs was frustrating, but it was also one of the most valuable learning experiences I’ve had. Now I know what to look for, how to diagnose moisture-related issues, and why proper filament storage and preparation matters just as much as print settings.

The Anycubic Kobra S1 is an excellent printer—but only when you treat your filament properly.

One response to “Scaling Up and the Humidity Problem: Troubleshooting the Anycubic Kobra S1”

-

This is an incredibly honest and helpful post, especially since you sell the Anycubic Kobra S1 Combo! It’s reassuring to see a company demonstrate such deep, real-world troubleshooting experience.

Leave a Reply