In older sci-fi movies, what we now recognize as 3D printing often appeared as pure fantasy — a futuristic machine that could “create anything out of nothing.” Seeing machines that could instantly make tools, food, or even body parts seemed like magic.

Today, what was once fiction has become real technology — and even advancing beyond what those movies imagined.

We can now print tools, homes, prosthetics, art, and even human tissues — layer by layer, idea by idea. It is now shaping our classrooms, industries, and future.

Just as printing on paper revolutionized how we spread knowledge, 3D printing is transforming our relationship with the physical world itself. And understanding where this technology came from helps us see where it’s taking us.

The Innovation Story: From Labs to Living Rooms

The history of 3D printing is a story of boldness and innovation. In 1984, when Charles Hull created the first stereolithographic printer, it seemed like science fiction to most people. Those first 3D printers were like the first computers – huge, expensive, and complicated to use. They lived in research labs, not schools or homes.

The 1990s brought refinement. The technology became more accessible to industrial sectors. This period saw significant breakthroughs in materials and printing methods. We can compare this stage to the development of personal computers – the technology was gradually leaving the laboratories and starting to find practical applications in real sectors.

Then came the early 2000s, and everything changed.

The RepRap project created a true revolution: a “self-replicating” printer – a machine that could print its own parts. Think about what the internet did for information access. RepRap did something similar for manufacturing – it made 3D printing technology accessible to regular people, not just corporations and researchers.

From 2010 onward, we entered a new era in educational 3D printing. Printers designed specifically for schools became as user-friendly as modern smartphones – simple to use, safe, and multifunctional.

Today, we’re seeing this technology take a central place in STEAM education worldwide.

The Transformational Potential of 3D Printing in the Future

As we stand on the cusp of a new era in manufacturing and innovation, 3D printing—also known as additive manufacturing—is poised to revolutionize countless aspects of our lives. What began as a tool for rapid prototyping in the 1980s has evolved into a technology capable of creating everything from custom prosthetics to entire buildings. Looking ahead to 2030 and beyond, experts predict explosive growth, with the global 3D printing market projected to surge from USD 16.16 billion in 2025 to USD 35.79 billion by 2030. Some forecasts even suggest it could exceed $40 billion by 2030, driven by broader adoption in mainstream manufacturing.

Revolutionizing Manufacturing: From Mass Production to Personalized Creation

In the future, 3D printing will democratize manufacturing, shifting from traditional assembly lines to on-demand, localized production. Imagine factories where AI algorithms optimize designs in real-time, generating complex geometries that reduce material waste by up to 90% compared to subtractive methods.

AI integration will be a game-changer, with generative designs crafting optimal shapes and monitoring processes to minimize errors. This could lead to “smart factories” where printers self-adjust based on environmental data, boosting efficiency and reducing costs.

Printing will become a standard technology, accessible even to small businesses and individuals.

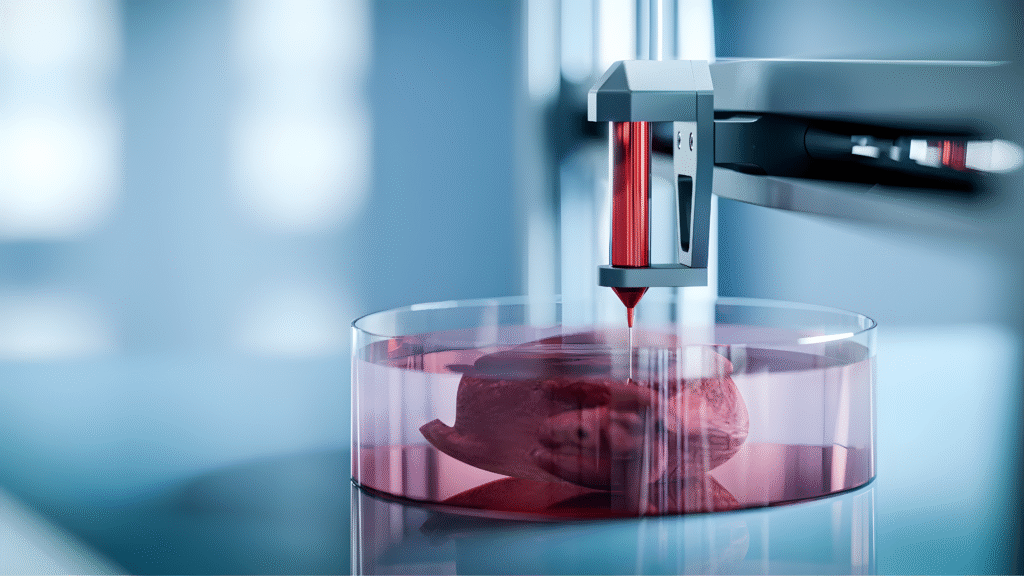

Transforming Healthcare: Bioprinting and Personalized Medicine

Perhaps the most profound impact will be in healthcare, where 3D bioprinting could solve the organ shortage crisis. By 2030, advancements in printing functional tissues—like hearts, kidneys, and livers—using patient-derived cells will make transplants rejection-free and widely available. Already, labs are printing viable blood vessels and skin grafts; the future promises fully functional organs, potentially ending waiting lists that claim thousands of lives annually.

Personalized medicine will flourish, with custom implants, drugs, and prosthetics tailored to individual genetics. Sustainable practices, such as using bio-inks from recycled materials, will align with global health goals.

This shift could reduce healthcare costs and improve outcomes, especially in underserved regions.

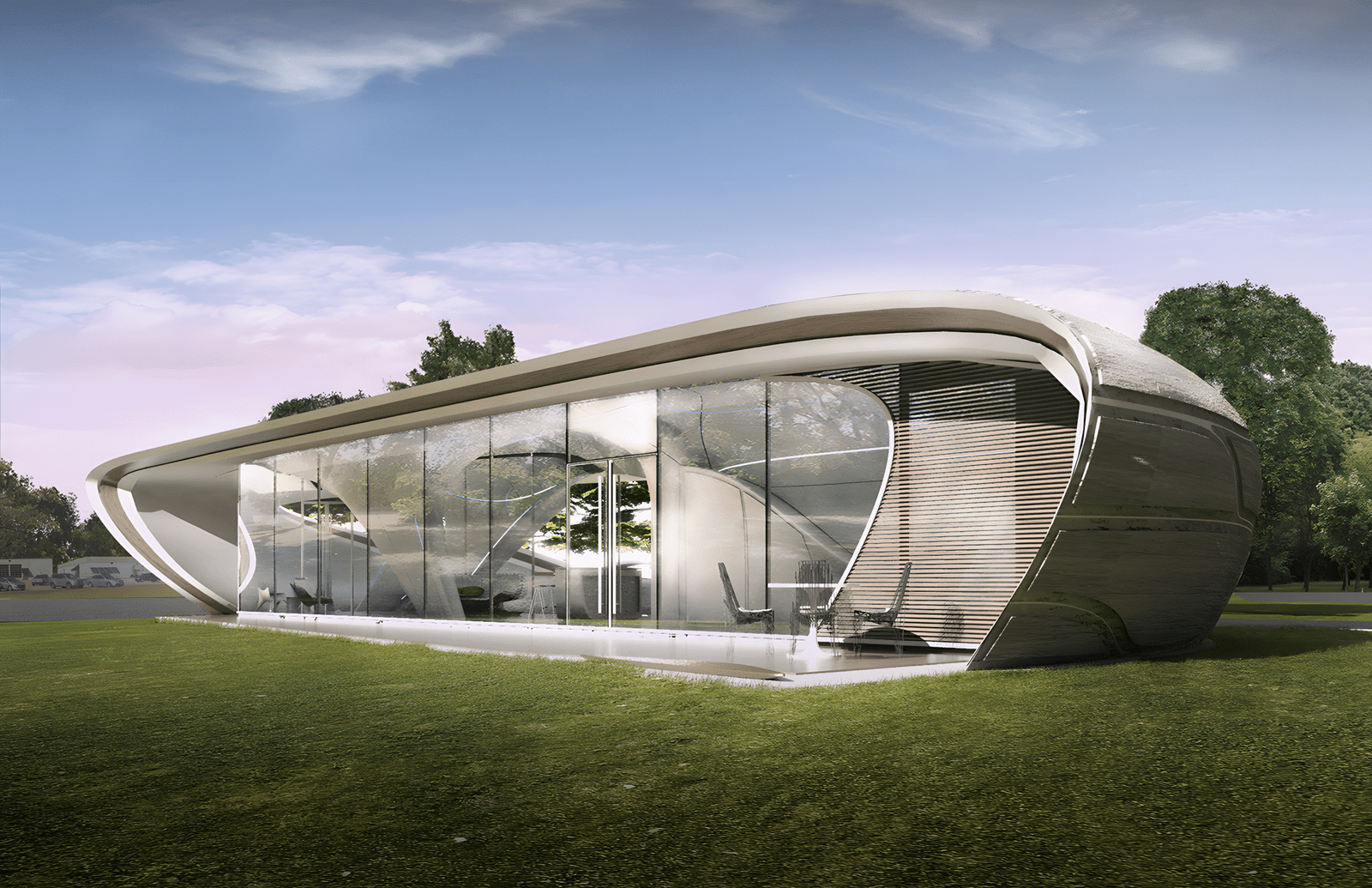

Redefining Construction: Building the Homes of Tomorrow

Advancements in additive manufacturing and digital integration will allow for modular homes printed in days, not months, addressing housing shortages worldwide.

Future homes could be free-form and customizable, incorporating smart materials that adapt to environmental conditions. In disaster-prone areas, printed structures using local or recycled materials will provide quick, resilient shelter.

This technology will also extend to infrastructure, like bridges and even space habitats, fostering sustainable urban development.

Enhancing Sustainability and Space Exploration

3D printing’s future is inherently green, minimizing waste through precise material use and enabling recycling of plastics, metals, and ceramics. By 2030, bio-based and self-healing materials will dominate, reducing the environmental footprint of manufacturing.

In space, in-situ resource utilization—printing tools and habitats from lunar or Martian soil—will be crucial for long-term missions. NASA’s plans for 3D-printed moon bases exemplify this potential. This shift could reduce healthcare costs and improve outcomes, especially in underserved regions.

Challenges and the Road Ahead

Despite the promise, challenges like regulatory hurdles, material limitations, and ethical concerns in bioprinting must be addressed. As the industry consolidates, ensuring equitable access will be key.

In conclusion, 3D printing’s transformational potential lies in its ability to make creation accessible, efficient, and innovative. By 2030, it won’t just change how we make things—it will redefine what we can achieve. What excites you most about this future? Share your thoughts below!

Considering the future transformational potential of 3D printing—from manufacturing to healthcare and construction—we should integrate this technology into classrooms, so that students can learn creation, problem-solving, and innovation from an early age, preparing them for the challenges of a technologically dynamic world and contributing to sustainable development.

Leave a Reply