-

Product on sale

Kobra S1 Combo

An ideal solution for fast, reliable, and creative 3D printing

Original price was: 2750,00 ₾.2550,00 ₾Current price is: 2550,00 ₾. -

Product on sale

High Speed Texture Grey PLA Filament

Fast, eco-friendly, high-quality 3D printing

Original price was: 95,00 ₾.75,00 ₾Current price is: 75,00 ₾. -

Product on sale

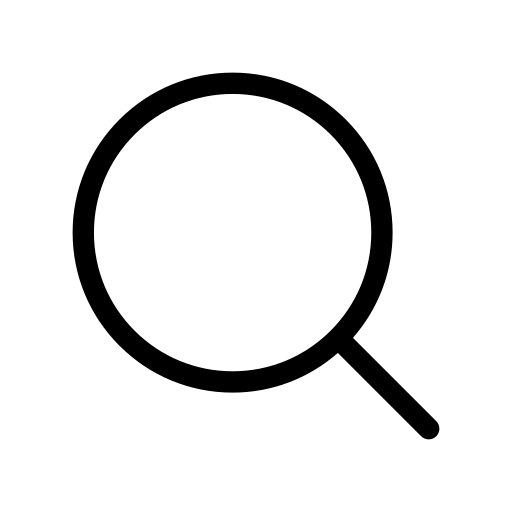

Adventurer 5M

Speed, reliability, and effortless setup in one sleek 3D printer.

Original price was: 1650,00 ₾.1450,00 ₾Current price is: 1450,00 ₾. -

Product on sale

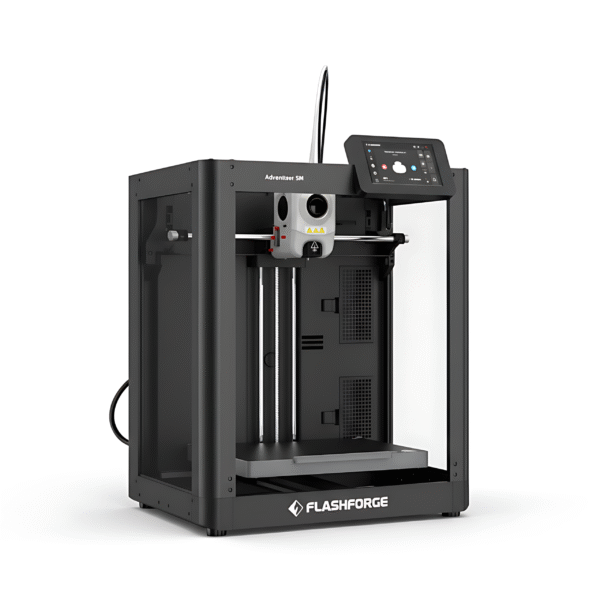

High Speed Bright Red PLA Filament

Print quickly with bright colors

Original price was: 95,00 ₾.75,00 ₾Current price is: 75,00 ₾. -

Product on sale

Enclosed Adventurer 5M

Enclosed design is ideal for home, school, or professional use.

Original price was: 1750,00 ₾.1450,00 ₾Current price is: 1450,00 ₾. -

Top

Product on saleHigh Speed Bright White PLA Filament

Excellent flow, no warping, and consistent extrusion

Original price was: 95,00 ₾.75,00 ₾Current price is: 75,00 ₾.

-

Product on sale

Festive Christmas Houses Vase

Original price was: 25,00 ₾.20,00 ₾Current price is: 20,00 ₾.

The School’s Journey

Implementation of 3D Printing in Education

Introduction

Green School operates across four branches with a clear educational philosophy: creating happy learning environments where children thrive. They focus on making the learning process engaging and meaningful, providing students with opportunities to build modern skills that will serve them in an ever-evolving world. Rather than viewing education as merely the transmission of knowledge, they believe in empowering children to become creators and innovators in their own right.

3D Printing Initiative: Timeline and Goals

Green School’s 3D printing program launched in March 2025, marking a significant shift in their educational approach. The key milestone was integrating 3D printing technology as an integral part of their curriculum, fundamentally transforming their learning concept from passively receiving knowledge to actively creating it. This initiative represents their commitment to experiential learning and technological literacy.

Equipment and Resources

They began with one Flash Forge Adventurer 5M printer installed at one of their branch locations. For software, they utilize Orca Slicer for preparing 3D models for printing. Their teachers source pre-designed files from online libraries while also guiding students in creating original designs. This equipment serves as both a teaching tool and a practical resource for school needs.

By the end of the spring semester, two additional branches had also acquired their own 3D printers, laying the foundation for school-wide integration.

Curriculum Integration

The 3D printer has been successfully integrated across multiple subject areas:

- Biology: Teachers print anatomical models for hands-on demonstrations.

- Mathematics: Three-dimensional shapes like dodecahedrons are printed to help students visualize complex geometric concepts.

- History: Ancient artifacts such as Greek theater masks are reproduced for tangible historical learning.

- Georgian Language: Cultural symbols like the Kakhetian lion are printed to connect language learning with cultural heritage.

Beyond using pre-designed files, students have begun creating their own designs, such as robots composed of basic 3D shapes. These projects blend technological skills with creative expression.

End-of-Semester Highlights

During the final month of the semester (before summer break), students in different branches completed small but meaningful projects:

- Georgian-Themed Board Game: One branch created a board game with the Georgian map as its base. Students designed and printed landmarks such as Svetitskhoveli and Svanetian towers, alongside figures representing Georgian kings, writers, and other cultural icons. The process—from converting 2D images into 3D models to printing—deeply engaged students, teaching them design, creativity, and technical problem-solving.

- Air Hockey Innovation: Another branch used their 3D printer to address a real-life problem. When their air hockey puck broke, teachers guided students through designing a stronger replacement. This became a significant learning opportunity as children discussed durability, design choices, and functional improvements—practical engineering thinking in action.

Teacher Training and Development

The program began with five trained teachers serving as in-house experts. By late spring, each of the two additional branches trained five more teachers who became capable of independently operating the printers. This created a strong foundation of skilled educators across Green School.

As of September, with the new academic year underway, training has expanded dramatically:

- Each branch now has around five fully trained teachers ready to independently implement 3D printing in their lessons.

- An additional 100 teachers are in the process of training and beginning to experiment with the technology in their classrooms.

This expansion ensures that 3D printing will soon be a part of learning experiences for a much larger number of students.

Student Engagement

Students were initially introduced to 3D printing through demonstrations of the printing process and simple tasks like filament changes. Now, they are increasingly involved in full projects—from concept design to finished product. The board game and air hockey projects showed that children can take ownership of the entire process, blending creativity, problem-solving, and teamwork.

Notable Projects and Applications

Alongside curriculum-specific activities, the printers have been used for:

- Practical repairs and replacements (e.g., sports equipment).

- Cultural and creative projects (e.g., Georgian-themed artifacts, board game).

- Student-driven prototypes (early stages of independent design work).

These examples highlight how 3D printing not only enriches the curriculum but also solves practical problems, making learning more relevant and applied.

Challenges and Solutions

Green School continues to navigate challenges such as:

- Technical issues (e.g., nozzle clogs), managed by their growing pool of trained teachers.

- Time management, as printing remains time-intensive, addressed by collaborative scheduling and monitoring.

Current Impact and Outcomes

Even within the first six months, the initiative has led to:

- Higher student engagement and enthusiasm for learning.

- Development of technical, design, and problem-solving skills.

- Stronger collaboration among students and teachers.

- A shift toward experiential, project-based learning.

While measurable academic outcomes are still emerging, the qualitative improvements to the learning environment are clear.

Future Plans and Vision

Looking ahead, Green School is committed to expanding 3D printing across all branches:

- More equipment: Each branch will eventually have 2–3 printers, including multi-color capabilities.

- Wider adoption: With 100+ teachers beginning training, 3D printing is moving toward becoming a standard teaching tool.

- Deep integration: Green School envisions 3D printing as a cornerstone of its educational model, fostering creativity, innovation, and applied knowledge.

This journey demonstrates how technology, when meaningfully integrated, transforms not only what students learn but how they learn—empowering them to become creators of knowledge rather than passive consumers.